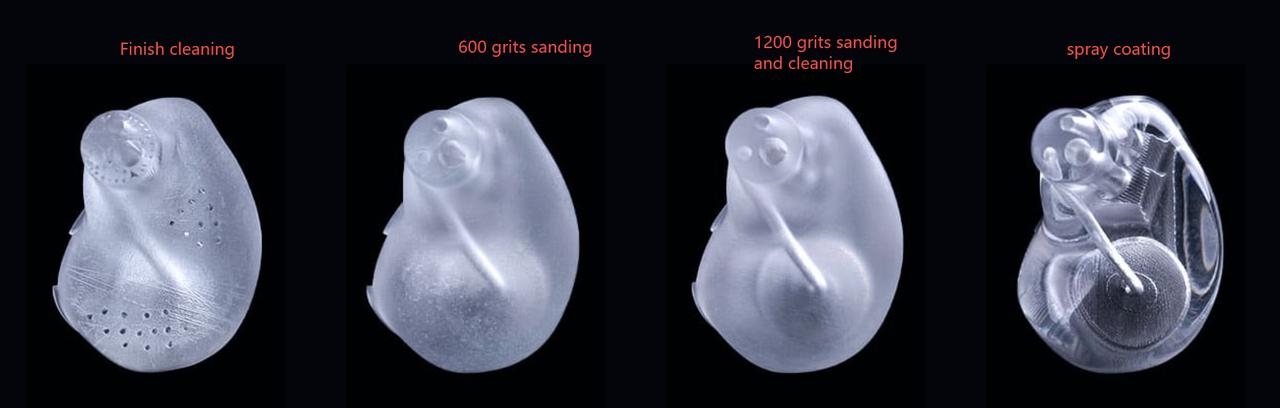

1.Manual Sanding

Use a range of wet sandpaper from 400 to 1200 grits to remove the print layer line and support points. It is recommended to increase the sandpaper level by 200 grit at a time. The scratches from the previous level should be eliminated before moving to the next level. The surface of the sample will have a fine frosted texture after 1200 grit.

2.Polish the part

You can first begin to clear the part with water to remove the grinding powder. Then use IPA or 95% alcohol with microfiber cloth to wipe the surface of the part to remove the residual powder and fingerprints.

3.Spray coating

Before coating, you should dry the part. If not, the coating quality will decline. The more you sand, the better the clarity. The spraying environment should be free of dust.

-

We recommend using clear acrylic spray or called automotive varnish. PAT10 binds well to most spray paint.

-

Another option is to use UV varnish. It has better overall finish than automotive varnish just like the printed part before polishing. The UV varnish needs to be cured under broad spectrum UV light, some of the UV coating could make the 3D printing parts brittle.Sample testing is recommended before use.