| Instructions on Application of Modeling PAWW20 | Project date: 09/10/2024 | Version: V1.0 |

¶ Material Information

¶ Overview

Modeling PAWW20 is a transparent, pink, water-washable resin material with balanced performance such as high dimensional and performance stability, strong detail reproduction and construction performance, and low water sorption. It meets the needs of washing print parts without alcohol as a material with little odor and low viscosity that is water-washable and is easy to wash.

¶ Recommendations on Applications

General, figures, miniatures and so on. Ideal for users who are allergic to alcohol or scenarios with no alcohol.

| Basic config. | |||

| Categories | Properties | Criteria | Values |

| Rigidity | Tensile Strength (MPa) | ASTM D638 | 32 |

| Flexural Strength (MPa) | ASTM D790 | 58 | |

| Flexural Modulus (MPa) | ASTM D790 | 1450 | |

| Toughness | Elongation at Break (%) | ASTM D638 | 16 |

| Impact Strength (Notched) (J/m) | ASTM D256 | 29 | |

| Essential Work of Fracture (J/m²) | ISO 20795 | 3230 | |

| Heat Resistance | Heat Deflection Temperature (0.45Mpa) (℃) | ASTM D648 | 49 |

| Physical Properties | Shore D Hardness | ASTM D2240 | 80 |

| Viscosity (mPa·s) | ASTM D4212 | 64 | |

| Water Sorption (%) | ASTM D570 | 5.9 | |

| Humidity and heat aging testing | GB/T 2423.3 | Passed | |

Note: The properties were obtained from printed objects after curing in Performance mode in HeyGears UltraCraft Cure.

¶ Design Suggestions

| Construction Performance Parameters | |

| Items | Resin tank(regular) |

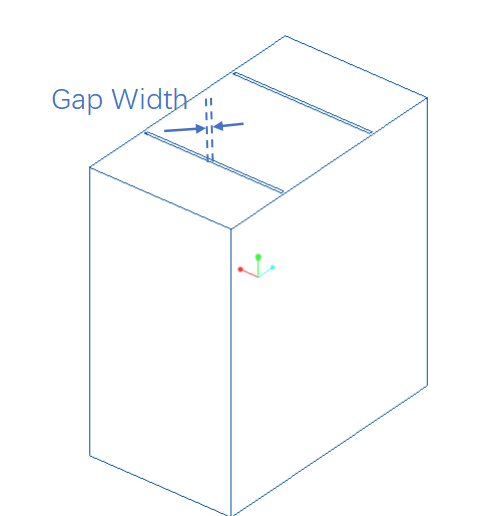

| Gap width (mm) | 0.15 |

| Overhang length (mm) | 0.8 |

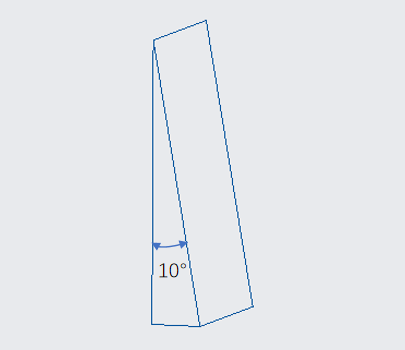

| No support offset (°) | 20 |

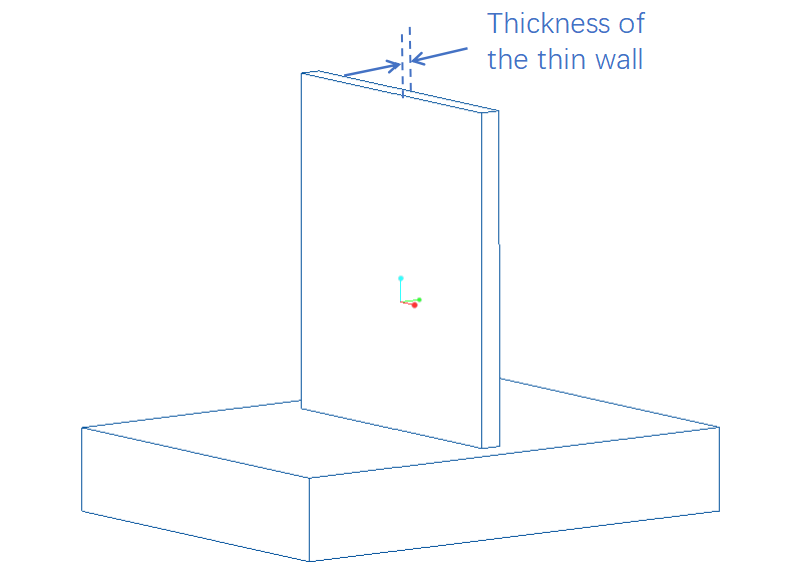

| Wall thickness (mm) | With baffle: 0.2 No baffle: 0.22 |

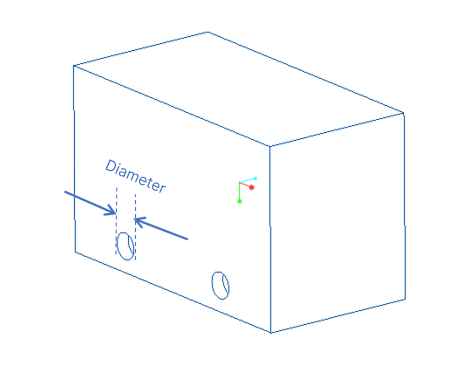

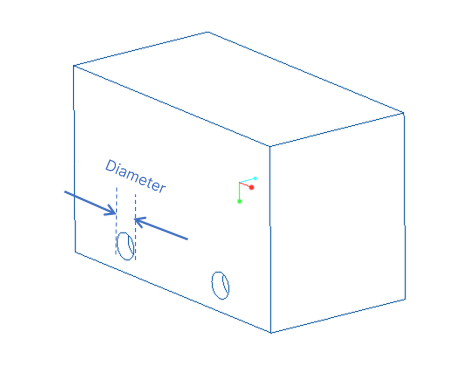

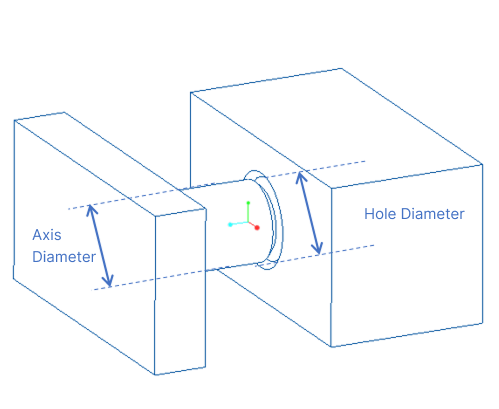

| Hole diameter (mm) | 0.4 |

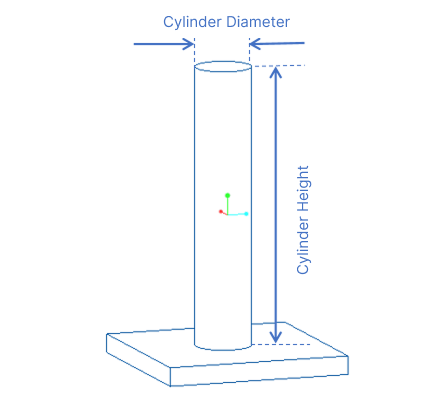

| Pillar diameter (mm) | 0.4 |

Note: The table presents the design requirements to guarantee at least the minimum construction performance of the material. Design parameters below them would lead to detail missing or print failure.

¶ Recommended Design Parameters

Design parameters are recommended below for various kinds of structures which guarantee the printing success rate.

¶ Thickness of Thin Wall Structures

¶ Hole

¶ Pillar

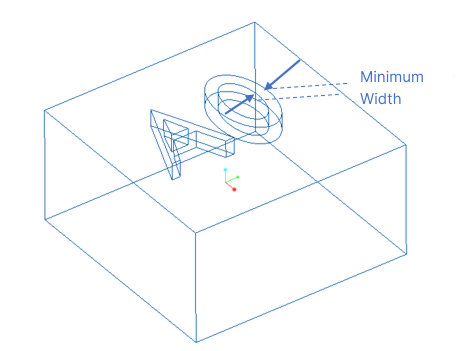

¶ Width of Raised & Depressed Details

¶ Drain Hole

¶ Acute Angle

¶ Gap

¶ Gap in Connections

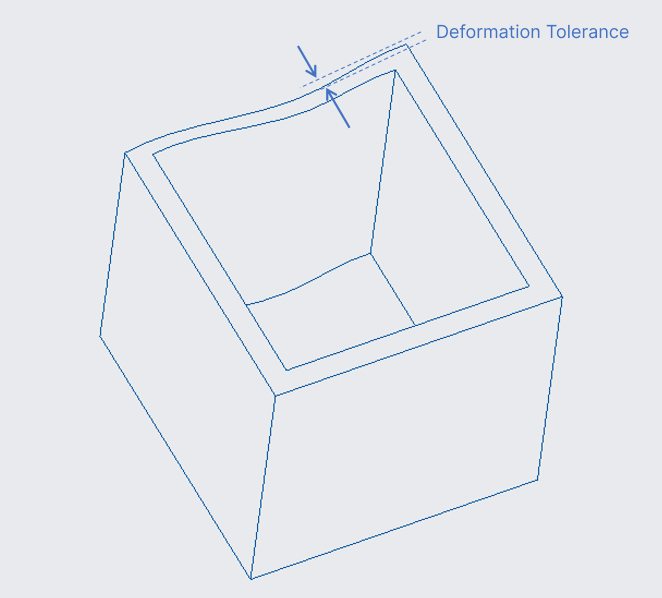

¶ Tolerance

¶ Process and Configuration

¶ Support Parameters

| Support parameters (regular resin tank) | ||

| Support areas | Parameter items | Default values |

| Support body | Lift height (mm) | 5 |

| Trunk diameter (mm) | 0.75 | |

| Overhang angle (°) | 40 | |

| Support density | Anchor distance (mm) | 2 |

| Border anchor distance (mm) | 2 | |

| Connection | Top diameter (mm) | 0.25 |

| Connection length (mm) | 1.5 | |

| Contact | Contact shape | Sphere |

| Top diameter (mm) | 0.30 | |

| Embedded depth (mm) | 0.20 | |

Notes: For a success print, it's advised not to change the support parameters when printing with a regular resin tank for the first time. Sufficient supports are needed on areas such as lowest points and islands, considering the center of gravity shifting during the process of printing, which might cause the object to shake and lead to misalignment. Appropriate improvements might be done on support parameters after the first print is successfully finished.

¶ Parameters for Slicing in Other Slicer Software (Not Recommended)

| Chitubox (printing with regular resin tank) | ||

| Support areas | Parameter items | Default values |

| Basic parameters | Lift height (mm) | 5 |

| Raft shape | Cross grid | |

| Raft thickness (mm) | 1.0 | |

| Overhang angle (°) | 45 | |

| Support density | Anchor distance (mm) | 2.0 |

| Connection | Top diameter (mm) | 0.3 |

| Connection length (mm) | 15 | |

| Trunk diameter(mm) | 0.95 | |

| Contact | Contact shape | Sphere |

| Top diameter (mm) | 0.4 | |

| Embedded depth (mm) | 0.2 | |

| Voxeldance Tango (printing with regular resin tank) | ||

| Support areas | Parameter items | Default values |

| Basic parameters | Lift height (mm) | 5 |

| Raft shape | Convex hull | |

| Raft thickness (mm) | 1.0 | |

| Overhang angle (°) | 45 | |

| Support density | Anchor distance (mm) | 2.0 |

| Connection | Top diameter (mm) | 0.3 |

| Connection length (mm) | 15 | |

| Trunk diameter(mm) | 0.95 | |

| Contact | Contact shape | Sphere |

| Top diameter (mm) | 0.4 | |

| Embedded depth (mm) | 0.2 | |

Note: It's advised to use a “safer” parameter configurations and have some tests first, as HeyGears printers cannot guarantee a high printing success rate for models sliced with a third-party slicer software which does not enjoy HeyGears print strategies.

¶ Recommended Washing

| Material Cleaning Parameters | ||||

| Material | Cleaning device | Washing settings | Cleaning solutions | Washing time |

| Modeling PAWW20 | UltraCraft Wash | Rotation speed 180r/min | 95% alcohol | 1min rough wash + 1min fine wash |

| - | - | Water | Rinse and wash for 2 min | |

Note: Rough wash refers to the behavior of washing off most liquid resin on the printed object with used water (used for more than 3 batches of prints); Fine wash refers to the behavior of well cleaning details of the printed object with clean water (used for less than 3 batches of prints).

¶ Recommended Curing

| Material Curing Parameters | ||||

| Material | Curing mode | Heat or not | Curing medium | Curing settings |

| Modeling PAWW20 | Rapid | No | Air | Room temperature for 5 min |

Note: Cure the print with HeyGears UltraCraft Cure. It’s advised to send the curing job from HeyGears Blueprint to the device first and then start curing on the device, as the job sent from Blueprint would enjoy a more advanced curing process and have an even better curing result.

¶ Precautions

¶ Precautions and Warnings

1.Please make sure to keep on protective wear (protective gloves and goggles) during the process.

2.Please avoid direct contact with liquid resin or the print parts after curing, to prevent irritation to the eyes or skin (which might cause sensitization).

3.If the product gets into the eyes, rinse immediately with clean water and contact a doctor.

4.If the product contacts with your skin, rinse immediately with clean water and wash thoroughly with soap.

5.The product should only be used after training by qualified personnel.

6.After each use, please be sure to immediately close the bottle cap to keep the bottle sealed.

7.Before use, please shake the resin well and it’s recommended to stir the resin in the resin tank before printing, to ensure that there is no significant sediment of the color powder.

8.After pouring into the resin tank, the resin should be kept away from light. If not printed for 3 days, the resin should be filtered and poured back into the resin bottle, avoiding staying for more than 7 days in the resin tank to prevent moisture absorption and degradation, which could lead to print failures.

¶ Storage and Transportation

1.The product should be stored in an indoor environment with a temperature of 15°C ~ 28°C, free from corrosive gases, well-ventilated, and protected from high temperatures, humidity, and direct sunlight.

2.The product should be transported in an environment with a temperature of 0°C ~ 45°C, and during transportation, it should be protected from heavy pressure, direct sunlight, and exposure to rain or snow.

3,The shelf life of the product is 18 months.

¶ Disposal

Please refer to the MSDS for precise information. Liquid resin should not be directly discharged. Please allow it to be fully cured into a solid under sunlight before disposing of it according to local regulations.