¶ I. Purpose

Guidelines and summary for sanding process of consumer-grade 3D print parts. This guidance is specifically applicable to the processing of larger exterior parts. Other types of print parts may use this as a reference for their sanding processes.

¶ Ⅱ. Confirming sanding requirements and tools preparation

¶ 2.1 Confirming sanding requirements

Confirm the sanding procedures based on different application scenarios.

| Number | Scenarios | Sanding process | Difficulty |

| 1 | Sanding of common internal structural parts | 150 mesh rough sanding | * |

| 2 | Support remain sanding based on sandblasting requirements | 150 mesh rough sanding | * |

| 3 | Sanding based on spraying requirements | 150 mesh rough sanding + 600 mesh fine sanding | ** |

| 4 | Sanding based on dyeing requirements | 150 mesh rough sanding + 600 mesh fine sanding | ** |

| 5 | Sanding of non-display appearance parts made of solid color material | 150 mesh rough sanding + 600 mesh fine sanding | ** |

| 6 | Sanding based on polishing needs | 150 mesh rough sanding + 600 mesh fine sanding + 1200 mesh fine sanding | *** |

| 7 | Sanding of display appearance parts made of solid color material | 150 mesh rough sanding + 600 mesh fine sanding + 1200 mesh fine sanding | *** |

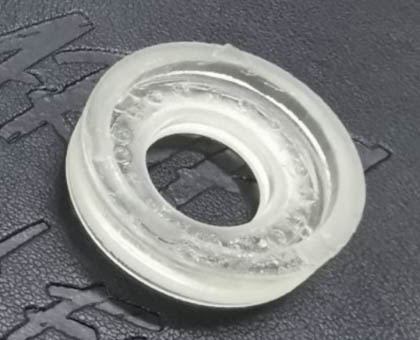

| 8 | Sanding of appearance parts made of transparent material | 150 mesh rough sanding + 600 mesh fine sanding + 1200 mesh fine sanding | *** |

¶ 2.2 Common sanding tools

Choose a proper tool and model based on your sanding needs (which scenarios, rough or fine sanding).

| Number | Tool | Image | Number | Tool | Image | |

| 1 | Sanding board |  |

7 | Sanding sponge |  |

|

| 2 | Sanding file |  |

8 | Abrasive disc (handpiece) |  |

|

| 3 | Round file |  |

9 | Diamond burr (handpiece) |  |

|

| 4 | Square file |  |

10 | Burr (handpiece) |  |

|

| 5 | Scraper |  |

11 | Sanding machine |  |

|

| 6 | Sandpaper |  |

12 | Handheld UV light |  |

¶ 2.3 Confirming sanding tools

Determine the finishing process and recommended tools based on different structures.

(1) Flat part

- Definition: Flat parts with a wall thickness of ≥1mm.

- Sanding Challenges: a. Large sanding area: Maintaining flatness can be difficult due to the large surface area.

- Definition: Part with curved structure with a wall thickness of ≥1mm.

- Sanding Challenges: a. Sanding regular curves: It can be difficult to maintain the correct curvature during sanding.

- Definition: Hollows and gaps (including fitting joints) at areas with a wall thickness of ≥1mm.

- Sanding Challenges: a. Limited or deep space: The small or deep groove space requires reaching in for sanding.

- Definition: A structure with a wall thickness of <1mm.

- Sanding Challenges: a. Risk of damage: Sanding thin-walled parts can easily lead to breakage.

- Definition: Small protrusions on a surface with a wall thickness of ≥1mm, such as hair-like features.

- Sanding Challenges: a.Close proximity of details: The small distances between features increase the risk of accidental damage during sanding.

- Definition: Layer lines on a surface with a wall thickness of ≥1mm.

- Sanding Challenges: a. Large area of layer lines: The extensive area requires significant time to sand effectively.

- Coarse sanding with 150 mesh.

- Fine sanding with 600 mesh.

b. Risk of over-sanding: It can be easily over-sanded, which can result in localized areas with insufficient wall thickness.

| Sanding Tools for Different Part Types | ||||||

| Part type | Tool type | Recommended tools | Recommended model | Tool features | Image | Difficulty |

| Flat part | Manual | Sanding board (composed of sandpaper + double-sided tape + sanding board, sandpaper is easy to replace) |

150 mesh, 600 mesh, 1200 mesh | Applicable to rough and fine sanding of parts with large flat surfaces and helpful in reaching evenness while sanding |  |

* |

| Sanding stick (Double-sided, with different roughness) |

150 mesh, 600 mesh | Applicable to fine sanding. Choose between coarser side and finer side according to the cutting amount. |  |

* | ||

| File | Cut grade 0.33~0.25 mm; Allowance 0.1mm-0.3mm | Applicable to quick rough sanding with large cutting amount, and service life is long. |  |

* | ||

| Electric type | Diamond burr (for handpiece) | Tungsten steel burr: 3*3 mm; Speed: 1000-50,000 RPM; Torque: 800 gf.cm | Applicable to quick rough sanding for mass-production. |  |

*** | |

| Sanding machine | 150 mesh | Applicable to quick rough sanding for mass-production. |  |

*** | ||

(2) Curved Surface

b. Risk of over-sanding: There is a tendency to sand too much, which can flatten the curved surface.

| Sanding Tools for Curved Surface Parts | ||||||

| Part type | Tool type | Recommended sanding tools | Recommended type | Tool features | Image | Difficulty level |

| Curved surface | Manual | Square file | Cut grade 0.33~0.25 mm; Tolerance 0.05 mm | Applicable to quick rough sanding of curved surfaces that are not demanding in precision. |  |

* |

| Sanding stick (double-sided, different coarseness available) |

150 mesh, 600 mesh | Applicable to quick rough sanding. Choose between coarser side and finer side according to the cutting amount |  |

* | ||

| Sandpaper (or sanding sponge) | 150 mesh, 600 mesh, 1200 mesh | Applicable to rough and fine sanding. It’s advised to keep the sandpaper firmly closed to the surface while sanding for curvature |  |

* | ||

| Electronic | Burr (for handpiece) | Emery tapered burr (fine); Speed: 1000-50,000 RPM; Torque: 800 gf.cm | Applicable to quick sanding of support remarks on curved surfaces |  |

*** | |

(3)Hollows & Gaps

b. Short sanding stroke: The limited sanding travel results in a small material removal rate, leading to longer processing times.

| Sanding Tools for Thin Wall Parts | ||||||

| Part type | Tool type | Recommended sanding tools | Recommended type | Tool features | Image | Difficulty level |

| Thin wall | Manual | Blade | Width: 1mm, 2mm, 4mm | Applicable to the bottom of hollows/gaps of all depth and width |  |

* |

| Tip of square file | Cut grade 0.33~0.25 mm; Tolerance 0.05 mm | Applicable to the side surface of hollows/gaps |  |

* | ||

| Tip of round file | Cut grade 0.33~0.25 mm; Tolerance 0.05 mm | Applicable to the side of round hollows/gaps |  |

* | ||

| Electric | Diamond burr (for handpiece) | Tungsten steel burr: 3*3 mm; Speed: 100-50,000 RPM; Torque: 800 gf.cm | Applicable to quick rough sanding of the side of hollows/gaps for mass production |  |

*** | |

(4) Thin-Walled Structure

b. Susceptibility to deformation: There is a high risk of warping or deformation during the sanding process.

| Sanding Tools for Different Structures (Thin Walled Surface) | ||||||

| Different structures | Tool type | Recommended sanding tools | Recommended type | Tool features | Illustration | Difficulty level |

| Thin walled surface | Manual | Blade | Width 1mm, 2mm, 4mm | Ideal for removing support points on thin walls. |  |

** |

| Sandpaper (or Sanding sponge) | 150 mesh, 600 mesh, 1200 mesh | Suitable for both coarse and fine sanding on thin walls; conforms closely to the surface for easy adjustment of sanding pressure. |  |

** | ||

| Electric | Needle (handheld sanding machine) | Diamond conical needle: fine mesh Rotation speed: 1000 - 50000RPM, torque: 800gf.cm |

Ideal for quickly removing support points on thin walls. |  |

** | |

(5) Detail 1#

Detail 2#

b. Corner layer lines: Layer lines in corners are difficult to sand thoroughly.

| Sanding Tools for Different Structures (Details) | ||||||

| Different structures | Tool type | Recommended sanding tools | Recommended type | Tool features | Illustration | Difficulty level |

| Detail 1 | Manual | Blade | Width 1mm, 2mm, 4mm | Ideal for removing detail supports. |  |

** |

| Sandpaper (or Sanding sponge) | 150 mesh, 600 mesh, 1200 mesh | Suitable for sanding support marks on details; allows for localized sanding. |  |

** | ||

| Electric | Needle (handheld sanding machine) | Diamond conical needle (fine sand) | Suitable for quickly sanding support points in details |  |

** | |

| Detail 2 | Manual | Sandpaper (or Sanding sponge) | 150 mesh, 600 mesh, 1200 mesh | Suitable for both coarse and fine sanding; sandpaper conforms closely to curved surfaces to ensure proper curvature. |  |

** |

| Electric | Cleansing cloth sanding head (Handheld sanding machine) |

Cleansing cloth sanding head : 180 mesh, 400 mesh, 1200 mesh. Rotation speed: 1000 - 50000RPM, torque: 800gf.cm |

Suitable for both coarse and fine sanding; quickly removes layer lines. |  |

*** | |

¶ Ⅲ. Sanding Process

¶ 3.1 Sanding Principles

Sanding Sequence:

1.Coarse Sanding (150 mesh): Remove support points and layer lines. After coarse sanding, layer lines should be invisible on the surface (see image below).

2.Fine Sanding (600 mesh): After fine sanding, sanding scratches should be invisible on the surface (see image below).

3.Polishing (1200 mesh): After polishing, the surface should be delicate and smooth (see image below).

Key sanding points:

1.Remove support points: Leave a small amount (approximately 0.5mm) to avoid filling in depressions; it’s better to sand down protrusions (see image below).

2.Avoid using dull tools: Using blunt water-cut pliers, spatulas, or sanding heads can easily damage the main structure (see image below).

|

|

| recommended | not recommended |

3.For all soft materials: Use water-cut pliers to remove support points (see image below).

Sanding Tools:

Use tools flexibly based on your habits and choose sanding tools that suit you best.

¶ 3.2 Case Study: Sanding Practice for Figurines

¶ 3.2.1 Confirming sanding requirements

1.The figurine will require a clear coat application for finishing.

2.The surface texture needs to be sanded, with the following mesh sequence applied to the exterior:

¶ 3.2.2 Confirming sanding tools

| Different structures | Recommended sanding tools | Tool features | Illustration | sanding points | Difficulty level |

| Plane | No. 3 file (fine tooth file), processing accuracy 0.05mm | Ideal for Rapid Coarse Sanding: High material removal rate and long lifespan. |  |

* | |

| Surface | Sandpaper (or Sanding sponge) 150-1200 mesh | Suitable for Fine Sanding: Sandpaper conforms closely to curved surfaces, ensuring consistent curvature. |  |

** | |

| Groove | Blade (Available in different sizes and widths) |

Effective for Various Grooves: Capable of sanding the bottoms of grooves with different depths and widths. |  |

* | |

| Thin walled | Sandpaper (or Sanding sponge) 150-1200 mesh | Perfect for Thin Walls: Allows for both coarse and fine sanding while closely adhering to thin wall surfaces, making it easy to adjust sanding pressure. |  |

** | |

| Detail 2 (layered pattern) | Sandpaper (or Sanding sponge) 150-1500 mesh | Great for Detail Work: Effective for sanding support point marks, enabling localized sanding. |  |

First, perform coarse sanding with 240 mesh until the layer lines are no longer visible. Next, use 600 mesh for fine sanding to eliminate any remaining scratches from the coarse sanding. |

** |

¶ IV. Common Issues and Solutions

¶ 4.1 Gaps left after sanding

| Step 1: Identify visible gaps at the support points. | Step 2: Dip a bamboo stick in resin and apply it to the gaps at the support points. | Step 3: Use a handheld UV lamp (365 nm wavelength) to closely irradiate the area for at least 10 seconds. |

|

|

|